Cooling Towers for Ice-cream Machines Series Economax

Series: Economax

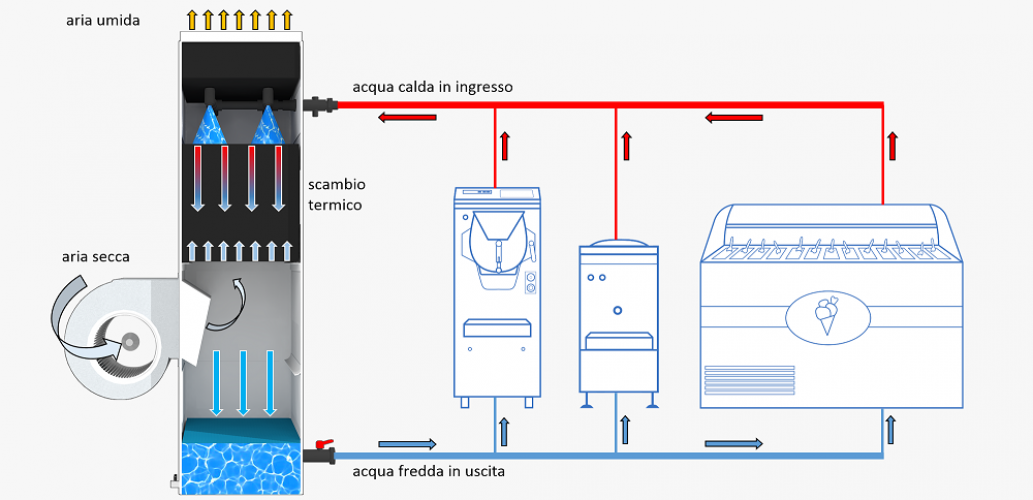

EVAPORATIVE CONDENSERS – COOLING SYSTEM

HOW DOES ECONOMAX® WORK

ECONOMAX® towers, our evaporative condensers made in Italy, have energetic efficiency as one of their main strengths, operating according to a fully natural principle.

The cooling effect is, in fact, obtained by spraying hot water coming from the ice cream machines on a wide surface of heat exchange.

The water, by going through the tower’s body, is hit by an air flow funnelled from the outside through a fan.

The air absorbs the humidity from the water causing a partial evaporation (less than 5% of the total) and extracting energy in the form of heat.

The result is lowered temperature of the water. The water is then collected in an internal tank and a pump brings it back into circulation.

Since it works with the evaporative principle, the ECONOMAX® evaporative condensers made in Italy can be installed both inside and outside, even under direct sunlight and with high temperatures, maintaining high efficiency in any conditions.

ESSENTIAL COMPONENTS FOR EFFICIENCY

– Fiberglass exterior

– PVC water distribution

– Fill design in electric welded PP

– Droplet separator in PP with EUROVENT certificate

– Return water float valve

– Centrifugal electric fan

– Water pressure pump with inverter

– Double fiberglass hatch for inspection and maintenance

– Stainless steel cart with wheels

– Touch-screen control panel

– Anti-dust filter in expanded metal

WATER ECONOMIZERS INSTALLATION

HYDRAULIC SYSTEM

This is how our water economizers made in Italy work. A semi-closed circuit is created, that connects input and output from the workroom’s machines with the two main hot and cold water collectors.

Through them, water flows into the cooling tower, is cooled down and is then sent to the system.

All instructions and specific information on the correct installation of our water economizers made in Italy are provided after purchase, with the direct technical support of the ECONOMAX® personnel.

Moreover, any necessary information is contained in the User’s Manual supplied with the machine.

INDOOR INSTALLATION

The dissipation of heat subtracted from the machines is carried out simply by low temperature vapour.

The internal installation is made by channelling the tower output towards the outside through a metal tube of suitable diameter.

The outgoing saturated air does not contain pollutants and does not require the use of external splits.

OUTDOOR INSTALLATION

The tower can be positioned outside the workroom, for example by placing it in a courtyard, in an open space or on the roof.

The only hole necessary in this case is one for the two main input and output collectors between the tower and the workroom machines.

The fiberglass case protects the machine and all its parts from any weather conditions, ensuring unparalleled durability.

Moreover, the tower can be exposed to direct sunlight without substantially altering its performance.

SMART ELECTRONICS FOR WATER SAVING DEVICES

MAXIMUM NOISELESSNESS AND SYNERGY:

CONSUMPTION ADAPTS TO THE WORK REQUIRED

The ECONOMAX® towers are water-saving devices made in Italy and are designed to work with the workroom machines only when necessary, in order to further limit electricity consumption and environmental impact.

Temperature and pressure detectors allow the tower to self-regulate depending on the thermal load to discharge and the necessary head, adapting to the system and optimising performance for each operational condition.

The PLC manages every aspect of our water-saving devices made in Italy in real time, from the continuous monitoring of the temperature to the functioning of the system.

Through a touch-screen panel, the integrated software allows you to easily and intuitively manage the different function modes (manual, automatic, timed) and to display and modify the operational parameters and plan maintenance.

ENERGY SAVINGS AND MAXIMUM NOISELESSNESS

Both the fan and the pump are regulated by an inverter, which allows incredibly noiseless operation. The machine starts in soft-start mode as the system’s number of revolutions gradually increases to the required speed.

“Night mode” further reduces noise emissions during the most critical hours, allowing the positioning of the tower even in sensitive, highly-populated areas.

TECHNICAL CHARACTERISTICS

• Control and regulation: The integrated touch-screen dashboard on the control panels allows immediate access to all the machine’s functions. The machine’s system measures the operational parameters

automatically and carries out a regular check in order to maintain the machine’s optimal efficiency.

• Structure: The entire machine is constructed using anti-corrosive materials. The fibreglass casing can hold the machine’s weight, guaranteeing an incredibly high resistance to external agents and time.

• Heat exchange: The PVC dashboards are structured to have an elevated surface of heat exchange in volumes contained. They are resistant to high temperatures and guarantee the highest performance.

• Fan: Direct-drive centrifugal fan with electronic control; the integrated inverter allows you to change its speed depending on the thermal load, keeping consumption and sound emissions to a minimum.

• Pump: Double-stage centrifuge with a stainless anti-corrosion impeller. It is controlled by a feedback inverter system through a pressure transducer, so as to guarantee the machine’s optimal performance in any situation.

• Bypass: The Solenoid Valve controlled by a temperature probe in the basin allows for the sudden lowering of the circuit’s water through the forced insertion of cold water from the external network when strictly necessary. The same valve carries out the proportional unblocking of recirculated water, maintaining limestone levels within the limits.

• Filters: The filter at the fan’s intake limits the circulation of impurities and food powder in the case that the machine is installed inside a shop.

• Communication: The integrated control system lets the operator know when to intervene with ANY necessary maintenance operations and allows the appropriate service team to be contacted quickly.

• Inspection and maintainance: The peepholes positioned on the fibreglass casing allow for a simple, immediate access to all the internal parts of the machine, facilitating inspection, cleaning and maintenance with extreme simplicity.

.jpg) Cooling Towers for Ice-cream Machines Series Economax 25-45

Cooling Towers for Ice-cream Machines Series Economax 25-45

.jpg) Cooling Tower for Ice-cream Machines Model Economax 100

Cooling Tower for Ice-cream Machines Model Economax 100

| Μοντέλο: | Economax 25 | Economax 45 | Economax 100 |

| Thermal Power: | 29kw/25.000Kcal/h | 52kw/45.000Kcal/h | 115kw/100.000Kcal/h |

| Water Flow Rate (m³/h): | 5 | 9 | 18 |

| Water Temperature (in): | 34ºC | 34ºC | 34ºC |

| Water Temperature (out): | 29ºC | 29ºC | 29ºC |

| Evaporated Water (m³/h): | 0,04 | 0,075 | 0,18 |

| Nozzles: | 4 | 4 | 4 |

| Fan Type: | Centrifugal EC | Centrifugal EC | Centrifugal EC |

| Fan Speed (rpm): | 2.800 | 2.800 | 2.800 |

| IP Protection: | 55 | 55 | 55 |

| Installed Power (kw): | 0,4 | 0,4 | 0,4 |

| Voltage: | 230/400/3/50hz | 230/400/3/50hz | 230/400/3/50hz |

| Dimensions: | 45x100x192cm | 60x120x203cm | 90x181x212cm |